SYSCON PlantStar BLOG

Real-Time Factory Data Becomes Key to Success for Manufacturers

Sep 9, 2021 5:00:00 PM / by PlantStar Team

Continuous improvement is what every manufacturer strives for. They constantly search for ways to increase yield, lower downtime, boost productivity, streamline scheduling, reduce operational costs, and improve profit margins.

One challenge has been delays between the time that steps in the manufacturing process were completed and when managers were informed of them. Recent advances enable Manufacturing Execution System (MES) and production and process monitoring solutions to provide suppliers with real-time data that enhances product management in numerous ways.

Traditionally, executives managed manufacturing plants reactively. They looked at historic reports to develop a feel for what happened in the supply chain and on the production floor and then took steps to mitigate problems and capitalize on opportunities.

Frankly, that approach was often slipshod. Information was stored in a hodgepodge of places: clipboards, spreadsheets, and even on sticky notes. Rather than a firm handle on how their supply chains were flowing, they often guessed what was happening, took action, and hoped for the best.

The recent advent of new technology, like the Internet of Things (IoT), data analytics, and modern MES solutions provide suppliers with visibility into current system performance. IoT adds intelligent sensors to traditionally unintelligent devices, so firms have smart rather than dumb factories. Big Data and data analytics provide easy access to information, so managers correlate data and enhance the business. In a growing number of cases, they gain access to up-to-date performance information, so they can make real time decisions, which benefit the enterprise in numerous ways.

Benefits of Real-Time Factory Data

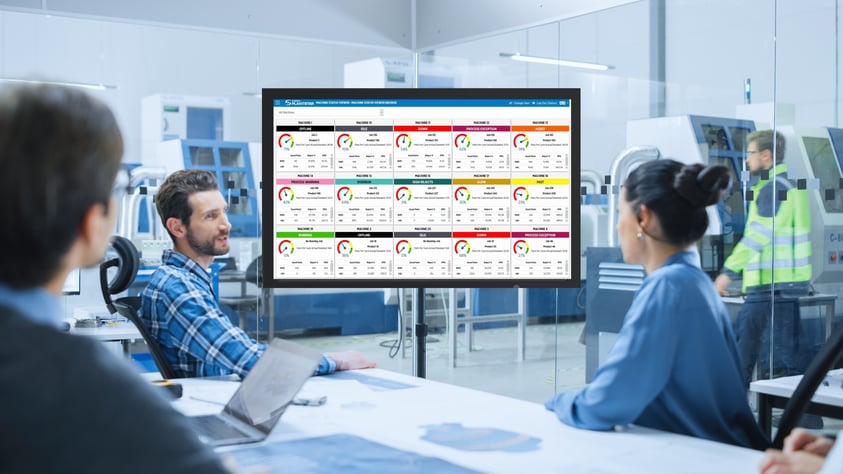

Manufacturers need real-time visibility into their production lines. This is accomplished by collecting data from all machines in the factory, recording that data into a database and then performing analysis to find areas for optimization.

Ultimately, real-time machine monitoring allows manufacturers to:

Respond to Problems Faster

Gaining access to such data helps them better manage the production floor. If a device is having problems (or even better, about to have an issue, a capability that predictive analytics delivers), the machine generates an alert that notifies managers about the snag. In a best case scenario, automatic feedback control is applied by the systems, and it makes short-term, temporary changes that keep it at the desired target (called the setpoint) in the face of process disturbances. In that way, the team minimizes disruption and boosts Overall Equipment Effectiveness (OEE).

Improve Production Time

Executives receive more timely and more accurate tracking production time, progress, and performance information, allowing them to better understand how many total parts have been created and have clearer views into performance of the beginning, middle, and end of their supply chains. With the information, they are better able to set expectations, so customers know when inventory will arrive and how many finished pieces they will receive.

Streamline Production Planning

Real-time monitoring is essential for streamlining and improving supply chain reconciliation. In most cases, vendors have intricate webs of connections that must function in sync if the company is going to run as lean and efficiently as possible. A problem in one area ripples through creating challenges in other places. Real-time data provides companies with information, so they understand how significant a problem will be. If shortages or overages arise, they are able to adjust and come closer to meeting shipping objectives. They also match personnel to manpower requirements and avoid problems, such as paying a lot of overtime to reach production goals as production run efficiency fluctuated.

Enhance Product Quality

Up to date information helps to ensure high levels of final product quality. Rather than waiting until the end of the run to discover poor quality product, they see how goods take shape at every step. By collecting data from all machines in the factory, manufacturers can identify machines with inadvertent variations in their product. The data includes information indicative of the variation (i.e., cycle time, temperature), enabling manufacturers to identify machines that require calibration or machine adjustments before defects are introduced into the final product. If a piece of machinery is nearing its end of life and performing below standard, they take corrective action ASAP. Consequently, systems operate more effectively, so there is less deviation from item to item. If a variability arises, it is caught early and has less of an impact than in the past. They lower scrap material volumes and improve overall yield.

Reduce Manual Labor

Currently, employees spend a great deal of time bouncing from one system to another to understand what is happening on the factory floor. These new tools include automation features that automatically perform such tasks. In addition, information is available at one’s fingertips and in a variety of devices, desktops, laptops, and smartphones. As a result, they spend more time on strategic initiatives, such as finding ways to tailor products, and less collecting and consolidating performance data. By collecting and analyzing machine and process data in real-time, manufacturers can better monitor their production lines and identify areas that need improvement or optimization. Manufacturers can then take action to improve efficiency by relocating stations, modifying processes, or scheduling changeovers more quickly.

Factories have long operated with inefficient, labor-intensive processes that controlled managers rather than vice versa. The emergence of new technology provides them with real time performance information, so they are able to flip the script from reactive to proactive management.

Real-time machine monitoring allows manufacturers to monitor the status of their production lines in real time, enabling them to identify areas for improvement, schedule downtime more efficiently and reduce costs by improving process efficiency.

As the manufacturing industry grows ever more complex, it becomes increasingly difficult to stay on top of all that is happening in production. Fortunately, advances in MES and production and process monitoring solutions have helped many suppliers keep up with the latest advancements in product management. These systems enable manufacturers to monitor their processes at every stage of development to ensure quality control and efficiency across the board. With advanced technology, manufacturers can now get even the most granular level of information in real-time to help make informed decisions about your production processes and quality control efforts.

For more insight into how MES solutions are changing what's possible in product management, continue to the articles below or visit our blog.

Topics: mes software

Subscribe to Email Updates

Posts by Topic

- Manufacturing Execution Systems (34)

- manufacturing solutions (16)

- MES 101 (12)

- Industry 4.0 (10)

- improve efficiency (9)

- mes software (9)

- mes solutions (9)

- Plastic Molding (8)

- Plastics Technology (8)

- Shop Floor Production (8)

- MES hardware (7)

- digital transformation (7)

- Reduce scrap (6)

- data-driven-decisions (6)

- lean manufacturing (6)

- process monitoring (5)

- product quality (5)

- Medical molding (4)

- lights-out manufacturing (4)

- manufacturing dashboard (4)

- production monitoring (4)

- Shop Floor Safety (3)

- supply chain management (3)

- ERP integration (2)

- Injection Molding Technology (2)

- defect collection (2)

- machine mes (2)

- process variables (2)

- digital strategy (1)

- labor gap (1)

- throughput (1)