SYSCON PlantStar BLOG

New year, same obstacles, new digital transformation solutions!

Jan 3, 2020 11:30:55 AM / by David Crowley

Happy New Year!

We here at SYSCON PlantStar hope you enjoyed the holidays and time away from work to refresh and relax.

Were your holidays headache-free?

Did your choices enable you to optimize the time you had with family and friends?

Sometimes, we overindulge. It happens! How many times have we partied too late or imbibed too much, only to pay for it later? We had a great time in the moment, but paid the price in regret.

You can think of it like borrowing happiness from tomorrow.

It's the same with your factory.

What choices are you making today that are going to cost you tomorrow, or on down the line?

If you don't have a manufacturing execution system (MES), you're not just borrowing happiness from tomorrow -- you're forfeiting profit.

Ouch. That's a headache you do not want.

Headache: scheduling

Maybe your schedulers are still adding work orders to machines by hand. But if a machine goes down unexpectedly, or you get the opportunity for a quick turn-around job that has a tight timeline, or your scheduler is out sick for a day or two, do you have processes in place that allow you to be agile and keep things running smoothly?

--OR--

Do you have to call your customers and attempt to extend your promised delivery date?

Do you have to turn down business because you can't pivot quickly enough?

Do you have to make do, just try to slog through as best you can, until your essential personnel return to the office?

Do you have the equivalent of a manufacturing hangover?

STOP DOING THAT!

There is a better way.

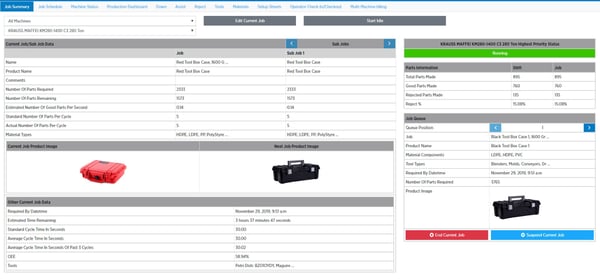

With PlantStar 4.0 MES, you can drag and drop on our interactive scheduler in real time.

You know at a glance which machines are available, when work orders will finish, and if you're going to have a tool conflict.

Rearrange as much as or little as you need with drag and drop. Try out if/then scheduling to optimize your runs and machine availability. Our system automatically alerts you of any problems with expected due dates, planned downtime for change-over or maintenance/repair, or asset conflicts -- before you make the changes live.

That means you fix problems before they even become problems!

Don't accept manufacturing hangovers tomorrow as inevitable.

There is a better way!

Headache: pencil-pushing

Maybe your operators are still waiting till end-of-shift to count parts, record anomalies, or identify rejects. But by then you might have excessive overrun. The operators may not remember exactly what caused a machine to slow or go down, or when, or what the precise circumstances were. You may be tight to deadline when your QA inspectors discover a bunch of flawed pieces.

At that point, you're borrowing happiness from tomorrow.

Your profitability is threatened, or at the very least, lessened.

Do you really want that?

Can you afford another manufacturing hangover?!

With PlantStar 4.0 MES, your operators have a real-time interface where they enter or confirm essential production data as it's happening.

If you have short cycle times, you can set a default window by which operators need to make changes or notes to system-gathered data.

Check the job summary screen, the machine status viewer, or the production event page to see at-a-glance whether your runs are on track to meet deadline. If they're behind, drill down into the reasons codes or the event logs to figure out what's wrong.

And then you can fix it.

NOW.

Before end-of-shift.

Before it's too late!!!

Headache: lack of clarity

Why does Machine A consistently outperform Machine B?

Why does Operator 1 produce half the parts Operator 2 produces in the same amount of time?

Why are parts from second shift nearly always to spec while so many parts from first shift go to reject?

Don't you want answers to questions like that?

Aren't you tired of just making your best guess, or hiring a whole new set of temp workers, or moving people to different machines, and hoping it'll get better?

STOP DOING THAT.

There is a better way.

With PlantStar 4.0 MES, you have data, not hunches.

You have data from digital inputs and outputs, sensors, USB ports, connections, software, your machine, materials, and people.

You have ALL the data.

You achieve digital transformation that lets you keep -- and maximize -- tomorrow's happiness.

Data answers your questions.

Data solves your problems.*

Data increases your profits.

Now that's making a difference.

Stop borrowing happiness from tomorrow and call SYSCON PlantStar today.

We'll walk you through how we connect the assets on your shop floor to optimize return on your investment and drive profitability for your business.

The better way IS PlantStar 4.0!

*MES data cannot cure your actual hangovers, and this is no substitute for medical advice from your trusted physician. For manufacturing questions, call us. For medical emergencies, dial 911.

Subscribe to Email Updates

Posts by Topic

- Manufacturing Execution Systems (34)

- manufacturing solutions (16)

- MES 101 (12)

- Industry 4.0 (10)

- improve efficiency (9)

- mes software (9)

- mes solutions (9)

- Plastic Molding (8)

- Plastics Technology (8)

- Shop Floor Production (8)

- MES hardware (7)

- digital transformation (7)

- Reduce scrap (6)

- data-driven-decisions (6)

- lean manufacturing (6)

- process monitoring (5)

- product quality (5)

- Medical molding (4)

- lights-out manufacturing (4)

- manufacturing dashboard (4)

- production monitoring (4)

- Shop Floor Safety (3)

- supply chain management (3)

- ERP integration (2)

- Injection Molding Technology (2)

- defect collection (2)

- machine mes (2)

- process variables (2)

- digital strategy (1)

- labor gap (1)

- throughput (1)

Related Articles